Pentair Centres of Excellence

Manufacturing hubs in Italy and Belgium keep Pentair quality, and European water, sustainable for life.

For over fifty years, Pentair has been at the heart of European water. It has been pouring its energy into delivering clean, safe water across the continent.

From residential and business solutions that help people move, improve and enjoy their water, to sustainable innovations and applications, Pentair makes the most of life’s essential resources.

Water treatment professionals insist on Pentair. Its innovation inspires. Its local support sparkles. But above all its quality is trusted. It flows through the company’s manufacturing, people and culture, and it passes on into its customers’ businesses.

Like treating water, quality is a process that needs to be measured, monitored and maintained. Through continual investment in Pentair people, local market knowledge and European production, Pentair has created ‘Centres of Excellence’ in Italy and Belgium that keep its quality, and European water, sustainable for life.

We asked Pentair Operations Manager, Davide Buccieri, to explain the ethos behind its European Centres of Excellence.

"Today Pentair is an international brand, manufacturing around the world, yet we have always held a firm belief in the importance of local presence. Much of our innovation and technology started life in our European Centres of Excellence and now filters around the globe. By manufacturing in Europe, for Europe, we retain control of the stringent quality standards which we, and our customers, demand. We can monitor and comply with the specific European certifications for water safety and materials. And at the same time ensure a resilient supply chain in uncertain times, whilst supporting customers, in their local language, wherever they live.”

Centres of Excellence:

Keeping it simple in a complex world

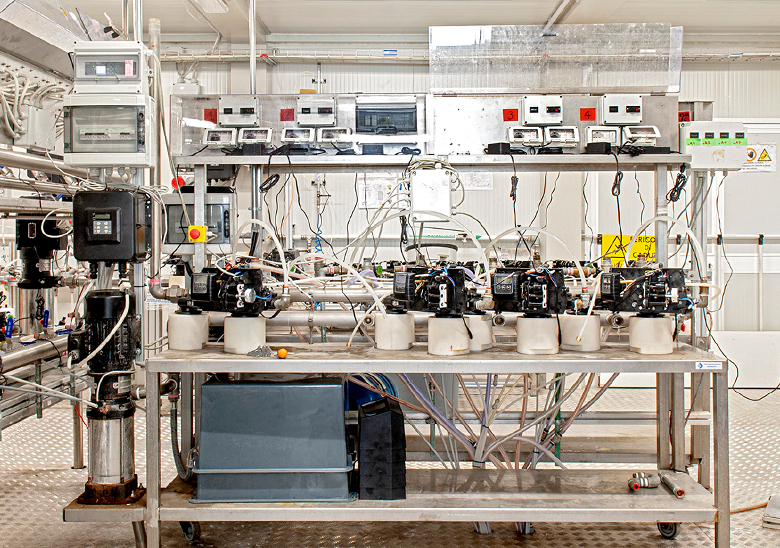

“Water treatment is a complex business. In Europe alone Pentair produces over 3000 items from 64 production lines. That’s why establishing Centres of Excellence keeps things simple. Each centre can focus on what they do best, complementing each other with common systems and resources. It means we can build specialist knowledge on materials, handling and production. Each centre adopts the Pentair Integrated Management Quality System (PIMS), learning, sharing and collaborating with one other. It’s a perfect partnership.”

Pentair European Production

- Pool equipment

- Water softening systems

- Drainage, irrigation pumps

- Storage tanks

- Pressure systems

- Filtration components

- Filtration systems

FACT FILES

PISA Centre of Excellence

About

- Founded: 1989

- Size: 14000 m2

- Employees: 200

- Production lines: 56

Highlight Technologies

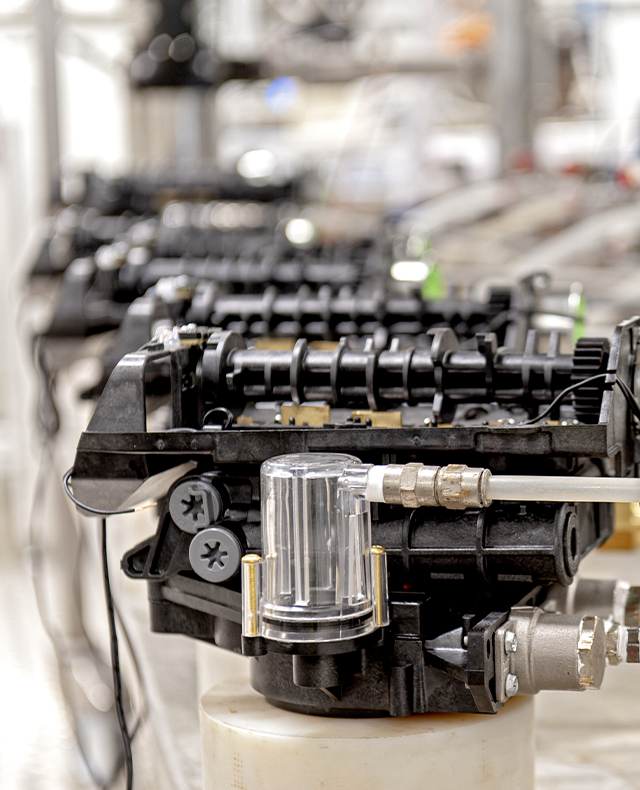

- New laboratory tests for valves

- Vision inspection system for

quality control during assembly

- 100% of valves are air tested

- New winding machine for motors

Key Outputs

Valves, pumps and valve assembly supply including:

- Irrigation & gardening pumps

- Drainage & sewage pumps

- Water pressurising

- Pool pumps

- SIATA, Fleck and Autotrol valves

Herentals Centre of Excellence

About

- Founded: 1964

- Size: 9000 m2

- Employees: 100

- Production lines: 8

Highlight Technologies

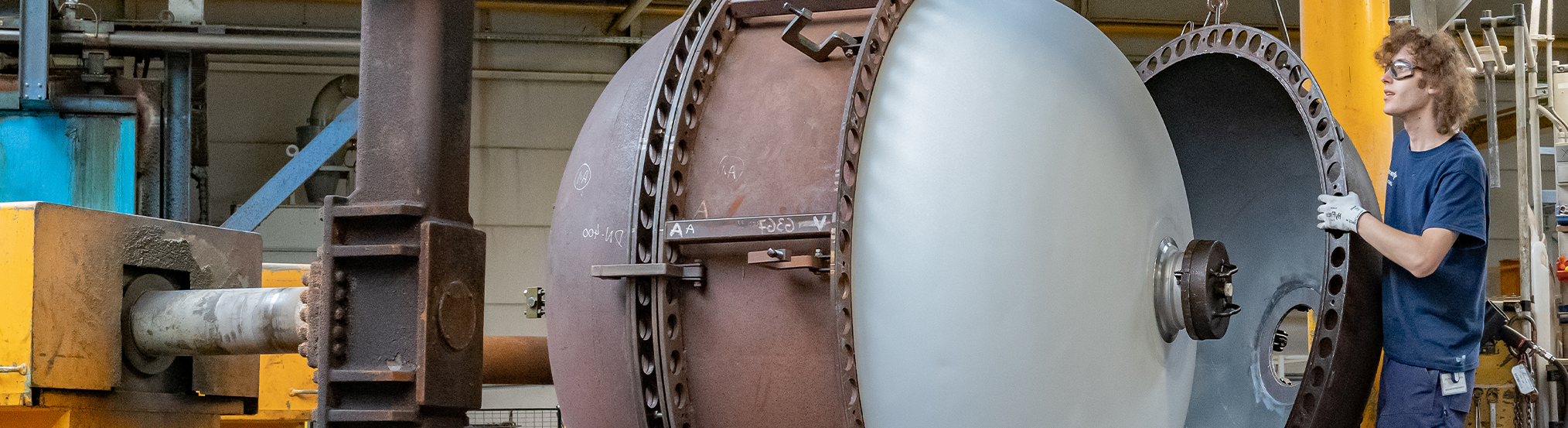

- New €1.7M blow moulding machine installed in 2021 with fully automated robotic handling

- Roto moulding and customised tank production facilities

- Automated shell pre-forming machine for pool filter line

Key Outputs

Tanks, softeners and system assembly including:

- Polyglass, resin, roto-moulded and blow moulded tanks

- Structural polyglass pressure vessels

- Softener systems including Evolio, Foleo, Avantapure, Riversoft and Waterfall

- Pool sand filters including Triton, Tagelus and Cristal-Flo

Pentair. We walk the walk.

“Quality is byword at Pentair. Both Centres of Excellence adopt our bespoke quality framework: Pentair Integrated Management System (PIMS) combining the very best of Lean Management and ISO 9001. We are also well on the way to achieving ISO certification for Safety (ISO 45001) and Environmental Standards (ISO 14001). In line with Lean Management waste reduction principles, we are also minimising our environmental impact. In Pisa alone, 100% of our production electricity comes from solar panels, we have installed our own water treatment plant for recycling our waste-water and we run a fleet of fully electric vehicles.

When it comes to action, we don’t just talk the talk…”