Being made in Europe helps Pentair steer through choppy waters

A partial meltdown of the global supply chain brought chaos in 2021. Fuelled by unprecedented consumer demand during COVID, everything had buckled under the strain. From raw materials to shipping containers, from dockyard space to warehouse capacity, everything was in short supply. Worldwide, manufacturers struggled to deliver. However, being geographically close to customers can give producers more control and help keep them wheels of industry turning.

We spoke to Steven Van Campenhout, Sales Director Components Pentair Europe on a turbulent 2021 for manufacturing, his hopes for 2022 and how, by manufacturing in Europe, Pentair were better placed than many to weather the storm.

A stellar year for component sales

“It would be safe to say that, after 27 years in this industry, I have seen some firsts in 2021, that could not have been predicted,” reflects Steven. “It has certainly been a year like no other.”

“Firstly, I was delighted to see record turnover in 2021. Despite an uncertain outlook after 2020, we exceeded our sales plans by double digits in both our industrial and residential markets. That growth is partly due to increased demand from existing and new customers, but also from many returning clients who have re-discovered the Pentair difference and brought their custom back to us. It is always good to welcome back business and we are grateful for the trust those customers place in us.”

“That growth has been sustained by the tremendous efforts put in by every member of the Pentair team. Not just in sales but in customer service, technical support and everyone who has contributed to provide an exceptional customer experience in a very challenging year.”

Global supply shortages make for a perfect storm

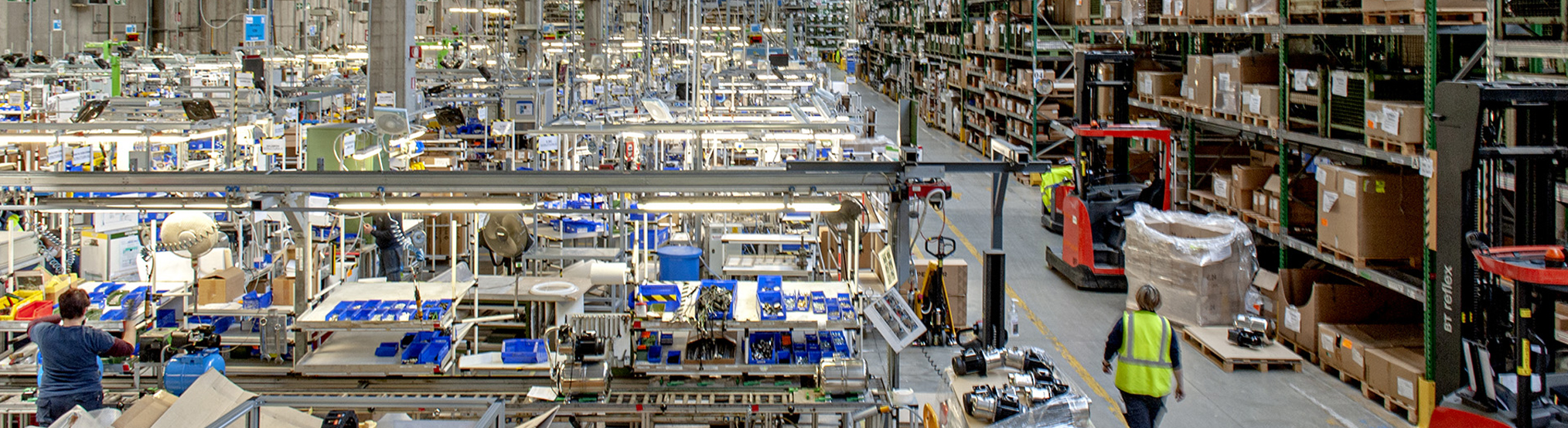

“Secondly, and for a number of reasons, 2021 has been the most challenging year I can recall. We have seen unprecedented raw materials shortages – from plastics to metals to electronics, essential to what we manufacture. That shortage has been compounded by a global bottleneck in docks, shipping containers and storage. Thankfully, by manufacturing at Centres of Excellence in Belgium and Italy, we have had more control over events than many, but it has not been easy.”

“This ‘perfect storm’ has inevitably led to delays fulfilling orders and sadly unexpected price rises.”

“We are doing everything we can to mitigate the impact on our customers,” explains Steven. “Raw material prices have rocketed or are simply not available. Where we can no longer source a part or material, we improvise, adapt or even manufacture an alternative. This inevitably adds to the costs but we have tried to absorb as many of those increases as possible. We have set up a dedicated Operational Taskforce who meet weekly to plan for the unexpected and keep the communications flowing to our customers. It has been a difficult time and again I thank our customers for their loyalty and understanding throughout the year.”

Closer proximity means better availability

Pentair is a global company with a strong European presence and local manufacturing specifically for the European market, of which it is justifiably proud. But it is not just a matter of pride.

“Being ‘Made in Europe for Europe’ has so many commercial benefits for our customers,” continues Steven, “especially during these disruptive times.”

“Being closer ultimately means better availability. We can better smooth out the peaks and troughs. Customers can order smaller quantities and shorter runs and we can often fulfil in a better delivery window than others who rely on manufacturing on distant shores.”

“Our European customers can also be confident that our products comply, and are certified, to the most stringent of standards across Europe. Our compliance team never stop in this everchanging landscape. In 2021, Pentair tanks became the first to meet the new requirements of the EU Drinking Water Directive, and the year also saw important approvals from the UK WRAS.”

“Our products continue to reflect the need of local markets and we are constantly enhancing our European language support. For example, 2021 saw the addition of Polish and Russian languages to our NXT2 valves interface – confirming our commitment to these important markets. Above all, our local presence is embodied by our people. I am frequently reminded by customers of the importance of being able to converse with anyone from our teams in their local language – it makes such a difference.”

Not out of the woods, but 2022 looks brighter

Steven does not expect the volatility caused by the raw materials shortages to go away any time soon but remains upbeat about Pentair being able to mitigate the worst in 2022.

“We have learned a lot in 2021 and are getting better at predicting what is to come,” he says. “We will re-double our efforts to make our own supply chain more robust and to deliver components as soon as we can, for new and open orders.”

“And despite the ongoing challenges we have some exciting plans for 2022. In the Spring we will be launching a new valve that adds IoT and Wi-Fi to its functionality. Internet control of home devices has accelerated and this new valve will be a welcome addition to our portfolio.”

“In addition, we will be extending the SIATA valve range with new products that will more than compensate for the loss of the much missed Fleck 5810 and 5812. And later in the year we aim to commence production of our highly-regarded Wellmate tanks, currently made by our American cousins, in our Herentals manufacturing Centre of Excellence in Belgium.”

“Whatever 2022 holds for manufacturing, there is one thing of which I can be sure. Pentair Europe will continue with our efforts to mitigate any disruptions to our customers’ businesses and, if we foresee a problem, we will keep up our communications programme so they will hear about it as soon as we do.”